Thin Film Custom Design

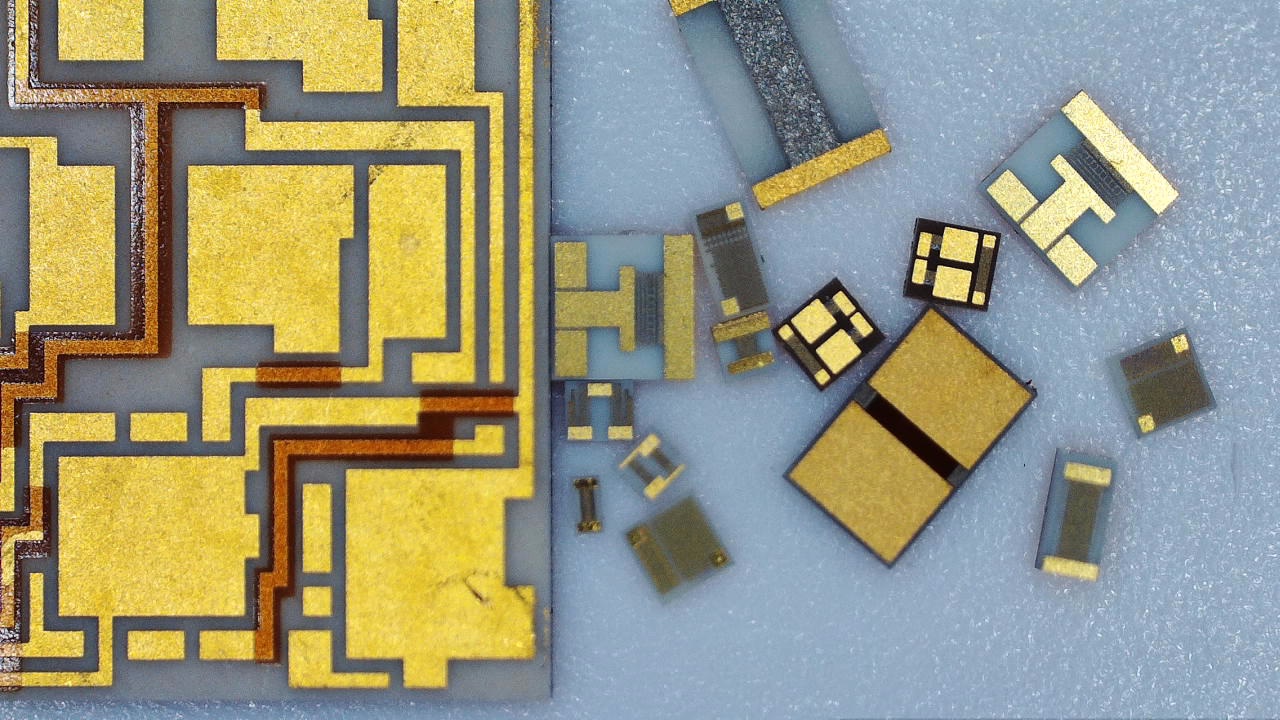

Thin Film Custom Design Products

Our advanced manufacturing methods ensure sheet uniformity, metallization adhesion, and thickness control allowing PPI to meet or exceed custom requirements from simple patterned submounts to highly complex boards that include: Transmission Lines Combines & Splitters, Interposers, Inductors, Filters, Direct Patterns, and Integrated tight tolerance resistors.

- Full In-House Design Capabilities

- Low NRE

- 100% Visual and DC Electrical Inspection

- Element Evaluation & Test Capabilities per MIL-PRF-55342 and MIL-STD-883

Design Characteristics

| Resistance Tolerance | ±0.01% to ±20% | |

| Resistance Ratio | 0.01% available | |

| TCR Tracking | ±2 ppm/°C | |

| Termination Material | Gold (Standard) | |

| Wafer: | Size | Up to 4 in x 4 in |

| Thickness Tolerances | As low as ±.5 mils for height matching applications | |

| Line Width Definition (Resistor) | 0.1 mils | |

| Line Width Definition (Conductor) | 0.2 mils | |

| Metals Available | Gold, Nickel, NiChrome, Palladium, Platinum, Tantalum, Tantalum Nitride, Titanium, Titanium Tungsten (TiW), Silver | |

| Specialty Materials | Metallization available on 1-6 sides Through-holes (vias), edge wraps, and custom laser cutouts |

| Patterning Processes | Full Photolithography capabilities and Lift-off patterning available |

| 100% Electrical | Laser test and trim with full mapping (read and record data) |

| Photolithography | Patterning, wet and dry etching |

| Electroplating | Nickel and Gold |

| Wafer Dicing | Silicon, Alumina, Quartz, Beryllium Oxide, Aluminum Nitride, and custom substrates |

| RF & DC Sputtering | Supporting Au, Pt, Ag, Ni, Pd, Ta, TiW, Ti, TaN, NiCr, and SiO₂. Custom plating stacks available. |

| Repackaging | Tape and Reel, Waffle Pack, Gel Pack, and Film Frame |

| Other Capabilities | Gold Filled Vias, Gold Bumping |

Resistive Materials

| Code | Material | Sheet Resistivity (Ω/Sq) |

Passivation | Standard TCR | Optional TCR |

| T | Tantalum Nitride | 5 Ω/sq – 300 Ω/sq | Ta₂O₅ (Self Passivating) | ± 150 ppm/°C | ± 50 ppm/°C |

| N | NiChrome | 5 Ω/sq – 250 Ω/sq | SiO₂ | ± 25 ppm/°C | ± 5 ppm/°C |

Substrate Materials

| Code | Material | Thickness | Dielectric Constant (@ 1MHz) |

Thermal Conductivity (W × m-1 × K-1) |

| 35 | Alumina (Al₂O₃) |

0.005″ – 0.025″ | 9.8 | 26.9 |

| 28 | Aluminum Nitride (AlN) |

0.005″ – 0.025″ | 8.7 | 170 |

| 25 | Beryllium Oxide (BeO) |

0.005″ – 0.025″ | 6.6 | 285 |

| 22 | Silicon (Si) | 0.005″ – 0.010″ | N/A (SiO₂ K= 3.8) |

149 (SiO₂ 1.38) |

| 20 | Quartz | 0.005″ – 0.010″ | 3.8 | 1.38 |

Testing

| Testing Performed | Specification/Standard |

| Visual Inspection | MIL-PRF-55342 MIL-STD-883 |

| Mechanical Inspection | MIL-PRF-55342 |

| DC Resistance | MIL-PRF-55342 MIL-STD-202 |

| High Temperature Exposure | MIL-PRF-55342 |

| Thermal Shock | MIL-PRF-55342 MIL-STD-202 |

| Resistance to Bonding Exposure | MIL-PRF-55342 |

| Wire Bonding Integrity | MIL-PRF-55342 |

| Life Test | MIL-PRF-55342 MIL-STD-202 |

Passive Plus offers a comprehensive range of Thin Film Components, designed to meet the diverse needs of the engineering community. PPI Thin Film Components are Made-to-Order and customized to specific applications. Offering precision, reliability, and customization options that cater to your unique requirements.

PPI Thin Film Components deliver tight tolerances, precision, and reliability for any engineering project. Explore each Thin Film type to determine the perfect fit for your application or contact PPI (sales@passiveplus.com) and our team can work with you to determine the best solution.

Once these specifications are confirmed, PPI will then supply the customer with a Spec Sheet with pricing and delivery options.

Please contact PPI directly at 631-425-0938 or by email at sales@passiveplus.com to start this process.