Microwave Edge Wrapped Resistors

Microwave Edge Wrapped Chip Resistors

Product Features

-

-

-

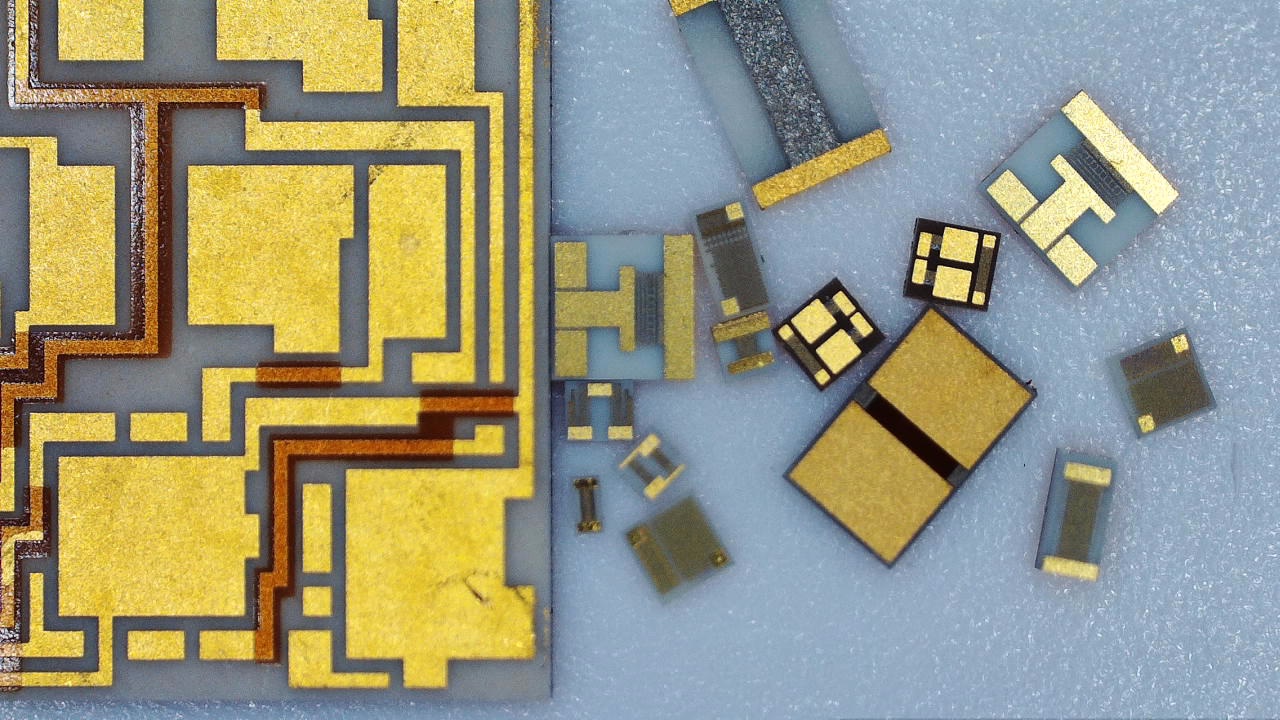

- Edge Wrap similar in construction to our standard surface mount wrap resistors, with half wrap and full wrap styles available.

- The addition of a microwave design allows for operation at frequencies up to 60 GHz.

- Can be used in Non-Magnetic Applications.

-

-

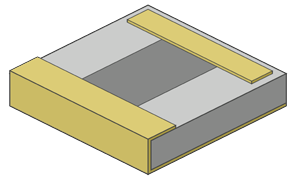

Half Wrap

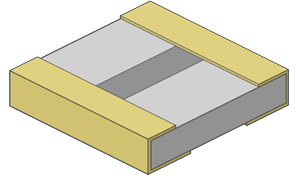

Full Wrap

Product Specifications

Resistance Range

-

- 2Ω to 5kΩ

Resistance Tolerance

-

- ±0.5% to ±20%, value dependent

Thin Film Microwave Edge Wrapped Resistors

Part Numbering

Example PPI Part Number: PMT128-40x20x10N200R0GQKW

Resistive Materials

Standard Thickness

| Code | Material | Passivation | Sheet Resistivity (Ω/Sq) |

Abs. Tolerance | Ratio Tolerance |

| T | Tantalum Nitride (TaN) |

Self Passivating Ta₂O₅ | 5 to 270 | From ±0.01% | From ±0.01% |

| N | NiChrome (NiCr) |

SiO₂ | 5 to 250 | From ±0.01% | From ±0.01% |

| L xW | Thickness |

| 12 x 09 | 5 mils |

| All other sizes | 10 mils |

For additional thickness requirements, please contact PPI

The standard dimensional tolerance for length and width is ± 2 mils. The standard dimensional tolerance for thickness is ± 1 mil.

Substrate Materials

| Code | Material | Thickness | Surface Finish | Dielectric Constant (@ 1MHz) |

Coefficient of Thermal Expansion (x10⁶/°C) |

Thermal Conductivity (W/m*K) |

| 35 | Alumina (Al₂O₃) |

0.005″ – 0.010″ | 2μ” – 3μ” | 9.9 | 7 (25°C to <300°C) |

26.9 |

| 28 | Aluminum Nitride (AlN) |

0.005″ – 0.010″ | 6μ” – 8μ” | 8.0 – 9.1 | 4.6 – 5.7 (25°C to <1000°C) |

170 |

| 25 | Beryllium Oxide (BeO) |

0.005″ – 0.010″ | <5μ” | 6.76 | 9 (25°C to <1000°C) |

285 |

Terminations

Resistance Value

| Code | Metallization | Description | Attachement Options |

| H | TaPd/Au | 1 Side Wrap | Wirebond, Non-Cond. Epoxy |

| M | TiW/Ni/Au | 1 Side Wrap | Wirebond, Cond. Epoxy, Non-Cond. Epoxy, Eutectic Attach Solder |

| S | TiW/Ni/Au Solder Dipped |

1 Side Wrap | Sn Solder Ball |

| J | TaPd/Au | 2 Side Wrap | Wirebond, Non-Cond. Epoxy |

| N | TiW/Ni/Au | 2 Side Wrap | Wirebond, Cond. Epoxy, Non-Cond. Epoxy, Eutectic Attach Solder |

| T | TiW/Ni/Au Solder Dipped |

2 Side Wrap | Sn Solder Ball |

Digits 1-4 are significant figures. Digit 5 is the number of zeros to follow. When required, “R” is used as a decimal point and the exponent is ommitteed.

Examples:

-

- Code 10001 = 10000Ω

- Code 10000 = 1000Ω

- Code 100R5 = 100.5Ω

Power Handling & Standard Resistance Ranges by Material and Case Size

Standard Power Resistors and High Power Resistors can be found under the below selectable tabs.

| Case Size | Alumina (35) |

AlN (28) |

BeO (25) |

||||

| mils (inches) |

Min (Ω) |

Max (Ω) |

Power Handling | Max (Ω) |

Power Handling | Max (Ω) |

Power Handling |

| 12×9 (0.012″x0.009″) |

1-3 | 25K | 50 mW | 25K | 200 mW | 25K | 400 mW |

| 14×12 (0.014″x0.012″) |

1-3 | 40K | 100 mW | 40K | 400 mW | 40K | 750 mW |

| 20×10 (0.020″x0.010″) |

1-3 | 60K | 100 mW | 60K | 400 mW | 60K | 750 mW |

| 15×15 (0.015″x0.015″) |

1-2 | 70K | 100 mW | 70K | 400 mW | 70K | 750 mW |

| 20×20 (0.020″x0.020″) |

1-2 | 125K | 250 mW | 125K | 1.0 W | 125K | 2.0 W |

| 30×20 (0.030″x0.020″) |

1-2 | 200K | 250 mW | 200K | 1.0 W | 200K | 2.0 W |

| 40×20 (0.040″x0.020″) |

1-2 | 250K | 250 mW | 250K | 1.0 W | 250K | 2.0 W |

| 30×30 (0.030″x0.030″) |

1-2 | 275K | 250 mW | 275K | 1.0 W | 275K | 2.0 W |

| 35×35 (0.035″x0.035″) |

1-2 | 300K | 250 mW | 300K | 1.0 W | 300K | 2.0 W |

| 40×40 (0.040″x0.040″) |

1-2 | 500K | 350 mW | 500K | 1.4 W | 500K | 2.8 W |

| 50×25 (0.050″x0.025″) |

1-2 | 300K | 350 mW | 300K | 1.4 W | 300K | 2.8 W |

| 60×30 (0.060″x0.030″) |

1-2 | 500K | 500 mW | 500K | 2.0 W | 500K | 4.0 W |

| 50×50 (0.050″x0.050″) |

1-2 | 700K | 500 mW | 700K | 2.0 W | 700K | 4.0 W |

| 60×60 (0.060″x0.060″) |

1-2 | 2M | 500 mW | 2M | 2.0 W | 2M | 4.0 W |

| 80×50 (0.080″x0.050″) |

1-2 | 2M | 500 mW | 2M | 2.0 W | 2M | 4.0 W |

| 100×50 (0.100″x0.050″) |

1-2 | 2.5M | 500 mW | 2.5M | 2.0 W | 2.5M | 4.0 W |

| 120×60 (0.120″x0.060″) |

1-2 | 3M | 750 mW | 3M | 3.0 W | 3M | 6.0 W |

| 100×100 (0.100″x0.100″) |

1-2 | 3.5M | 750 mW | 3.5M | 3.0 W | 3.5M | 6.0 W |

| Case Size | Resistance Range | Power Handling | |||

| mils (inches) |

Min (Ω) |

Max (Ω) |

Alumina (35) |

AlN (28) |

BeO (25) |

| 12×9 (0.012″x0.009″) |

– | – | – | – | – |

| 14×12 (0.014″x0.012″) |

– | – | – | – | – |

| 20×10 (0.020″x0.010″) |

2 | 1000 | 250 mW | 1.0 W | 2.0 W |

| 15×15 (0.015″x0.015″) |

2 | 1000 | 250 mW | 1.0 W | 2.0 W |

| 20×20 (0.020″x0.020″) |

2 | 1000 | 500 mW | 2.0 W | 4.0 W |

| 30×20 (0.030″x0.020″) |

2 | 1000 | 500 mW | 2.0 W | 4.0 W |

| 40×20 (0.040″x0.020″) |

2 | 1000 | 750 mW | 3.0 W | 6.0 W |

| 30×30 (0.030″x0.030″) |

2 | 1000 | 750 mW | 2.0 W | 6.0 W |

| 35×35 (0.035″x0.035″) |

2 | 1000 | 1.0 W | 4.0 W | 6.0 W |

| 40×40 (0.040″x0.040″) |

2 | 1000 | 1.0 W | 4.0 W | 6.0 W |

| 50×25 (0.050″x0.025″) |

2 | 1000 | 1.0 W | 4.0 W | 6.0 W |

| 60×30 (0.060″x0.030″) |

2 | 1000 | 1.4 W | 5.0 W | 10.0 W |

| 50×50 (0.050″x0.050″) |

2 | 1000 | 1.4 W | 5.0 W | 10.0 W |

| 60×60 (0.060″x0.060″) |

2 | 1000 | 1.4 W | 5.0 W | 10.0 W |

| 80×50 (0.080″x0.050″) |

2 | 1000 | 2.8 W | 10.0 W | 15.0 W |

| 100×50 (0.100″x0.050″) |

2 | 1000 | 2.8 W | 10.0 W | 15.0 W |

| 120×60 (0.120″x0.060″) |

2 | 1000 | 2.8 W | 10.0 W | 15.0 W |

| 100×100 (0.100″x0.100″) |

2 | 1000 | 2.8 W | 10.0 W | 15.0 W |

Typical PPI commercial testing includes 100% visual inspection, 100% electrical testing with short time overload, and TCR sampling.

Our parts meet of exceed additional MIL-PRF-55342 and MIL-STD-202 requirements.

Resistance Tolerance

Temperature Coefficient

Power Handling

| Code | Tolerance |

| D | ±0.5% |

| F | ±1% |

| G | ±2% |

| H | ±3% |

| J | ±5% |

| K | ±10% |

| L | ±15% |

| M | ±20% |

| Code | TC | Material | |

| Tantallum Nitride (TaN) |

NiChrome (NiCr) |

||

| Q | ±150PPM/°C | Standard | – |

| V | ±100PPM/°C | Yes | – |

| W | ±50PPM/°C | Yes | Yes |

| X | ±25PPM/°C | – | Standard |

| Y | ±10PPM/°C | – | Yes |

| Z | ±5PPM/°C | – | Yes |

| Code | Watts |

| A | 10 mW |

| B | 20 mW |

| C | 50 mW |

| D | 75 mW |

| E | 100 mW |

| I | 125 mW |

| F | 150 mW |

| O | 200 mW |

| G | 250 mW |

| M | 350 mW |

| R | 400 mW |

| H | 500 mW |

| J | 750 mW |

| K | 1.0 W |

| U | 1.4 W |

| L | 2.0 W |

| Y | 2.8 W |

| N | 3.0 W |

| P | 4.0 W |

| Q | 5.0 W |

| Z | 6.0 W |

| S | 10 W |

Packaging

General Properties

Testing

| Code | Style |

| W | Waffle Pack (Standard) |

For additional packaging options, please contact PPI.

| Operating Temperature | -55°C to +150°C |

| Storage Temperature | -65°C to +150°C |

| Operating Frequency | DC to 60 GHz |

| Voltage Rating | 100V maximum |

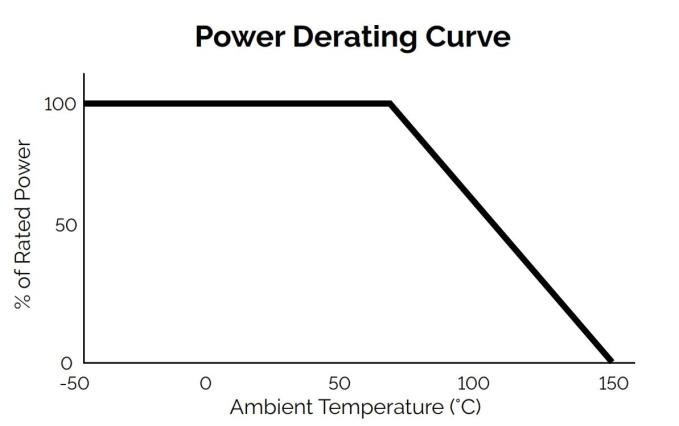

| Power Derating (See Chart below) |

Full power up to 70°C Derated linearly to zero power at 150°C |

| Testing Performed | Specification/Standard |

| Visual Inspection | MIL-PRF-55342 MIL-STD-883 |

| Mechanical Inspection | MIL-PRF-55342 |

| DC Resistance | MIL-PRF-55342 MIL-STD-202 |

| Resistance Temperature Characteristics (TCR) | MIL-PRF-55342 |

| Short Time Overload | MIL-PRF-55342 |

| High Temperature Exposure | MIL-PRF-55342 |

| Thermal Shock | MIL-PRF-55342 MIL-STD-202 |

| Resistance to Bonding Exposure | MIL-PRF-55342 |

| Wire Bonding Integrity | MIL-PRF-55342 |

| Life Test | MIL-PRF-55342 MIL-STD-202 |

Performance Specifications

Higher power ratings, additional sizes, and custom resistors available. Please contact sales@passiveplus.com.

Passive Plus offers a comprehensive range of Thin Film Components, designed to meet the diverse needs of the engineering community. PPI Thin Film Components are Made-to-Order and customized to specific applications. Offering precision, reliability, and customization options that cater to your unique requirements.

PPI Thin Film Components deliver tight tolerances, precision, and reliability for any engineering project. Explore each Thin Film type to determine the perfect fit for your application or contact PPI (sales@passiveplus.com) and our team can work with you to determine the best solution.

Once these specifications are confirmed, PPI will then supply the customer with a Spec Sheet with pricing and delivery options.

Please contact PPI directly at 631-425-0938 or by email at sales@passiveplus.com to start this process.

+1 631-425-0938

+1 631-425-0938 Contact

Contact Search

Search C.A.P. Product Lookup

C.A.P. Product Lookup Translate

Translate